NEW YORK CITY DEPARTMENT OF TRANSPORTATION

Brooklyn Bridge

EPM has provided Resident Engineering and Inspection Services for all hazardous material activities during the Brooklyn Bridge rehabilitation project since 2010.

EPM’s responsibilities include:

Monitor lead containing paint disturbance emissions using Method 22, DataRam and Total Suspended Particulates (TSP) adhering to Lead 40 CFR 50

Ensure contractor compliance with OSHA Lead in Construction Standard 29 CFR 1926.62

Ensure contractor compliance with testing, handling, labeling, storing, manifesting, and track hazardous and universal wastes transported off-site

Frequently visually inspect work area to verify containment integrity

Prepare Daily Environmental Compliance Report

Review monthly industrial hygiene reports of lead disturbance activities

Conduct asbestos materials surveys and air monitoring during remediation

Monitor daily ambient noise levels to meet NYS Noise Code requirements

Williamsburg Bridge

Since 1998, EPM has provided Resident Engineering and Inspection Services for all hazardous material activities during the Williamsburg Bridge Reconstruction.

EPM’s responsibilities included:

Monitor lead containing paint disturbance emissions using Method 22, DataRam and Total Suspended Particulates (TSP) adhering to Lead 40 CFR 50

Ensure contractor compliance with OSHA Lead in Construction Standard 29 CFR 1926.62

Ensure contractor compliance with testing, handling, labeling, storing, manifesting, and track hazardous and universal wastes transported off-site

Frequently visually inspect work area to verify containment integrity

Prepare Daily Environmental Compliance Report

Review monthly industrial hygiene reports of lead disturbance activities

Conduct asbestos materials surveys and air monitoring during remediation

Air monitor area for toxic and potential harmful chemical and microbiological agents including lead and silica

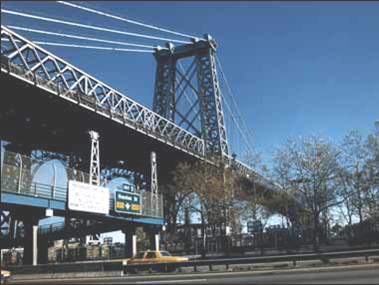

Manhattan Bridge

For 14 continuous years, EPM has provided Resident Engineering and Inspection Services for all hazardous material activities under multiple Manhattan Bridge Rehabilitation Contracts.

EPM has monitored lead containing paint disturbance emissions during abrasive blasting and steel rehabilitation of the Manhattan Bridge at the suspended and approach spans, the travelers platform, the maintenance platforms at the towers and anchorages, and canopies for both towers; the lower roadway suspended span; the steel support structures within the anchorages; and all the main cables, suspender ropes and related hardware.

Responsibilities included:·

Ambient air monitoring using Method 22, DataRam and Total Suspended Particulates (TSP) adhering to Lead 40 CFR 50

Waste collection oversight including handling, storing, classifying, testing, transporting, and disposing of hazardous materials

Final documentation summarizing all lead disturbance activity monitoring

Radiation monitoring

Roosevelt Island Bridge

EPM has conducted asbestos, lead and pigeon waste investigations, provided subsequent abatement oversight and construction support services during the reconstruction of the Roosevelt Island Bridge.

The investigations determined and characterized appropriate management of health and safety precautions, and recommended disposal and remediation actions for any contaminated material identified during construction activities.

EPM provided supervision and support services during the removal of asbestos, lead, and any additional hazardous materials encountered with remediation.

EPM’s ensured all remediation work conducted was performed in accordance within the technical specifications and all applicable laws, codes, rules and regulations, and all applicable licenses of the abatement contractor were current. All requisite air monitoring was performed, and all contractor submittals were reviewed and commented on by EPM.

Following completion of any remedial activity, EPM submitted status reports to the Project Engineer and NYCDOT.